Production of houses made of glulam and half-timbered

The ZAVDOZ Group of Companies is a full—cycle manufacturing holding. Thanks to the presence of our own production workshops with modern equipment, a logging complex and an architectural bureau, we produce truly high-quality houses.

Sawmilling

Drying

Preliminary gouging and sorting of plots

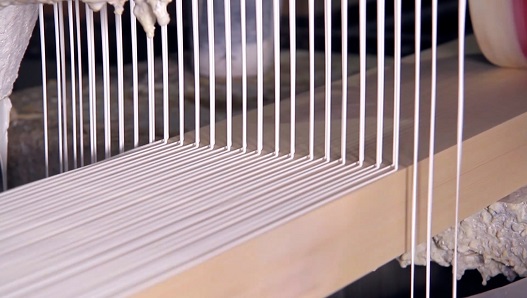

Splice

Cutting and applying glue

Gluing of timber

Gouging of glulam

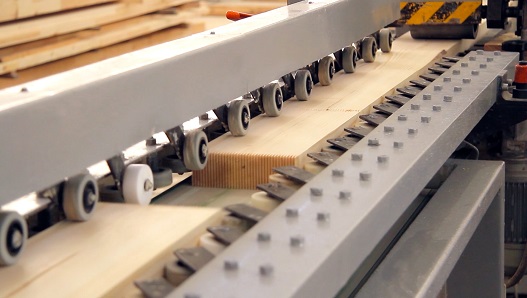

Cutting of glulam parts

TOPMASTER – a machine for cutting parts of houses in automatic mode, both simple and complex architecture.Accuracy: 1-3mm at 12 meters. Submission – capture.

Hundegger - 3x-coordinate machine for automatic cutting of complex parts of half-timbered houses and rafter systems. Ultra-precise. Submission – capture

Antiseptization

Packaging